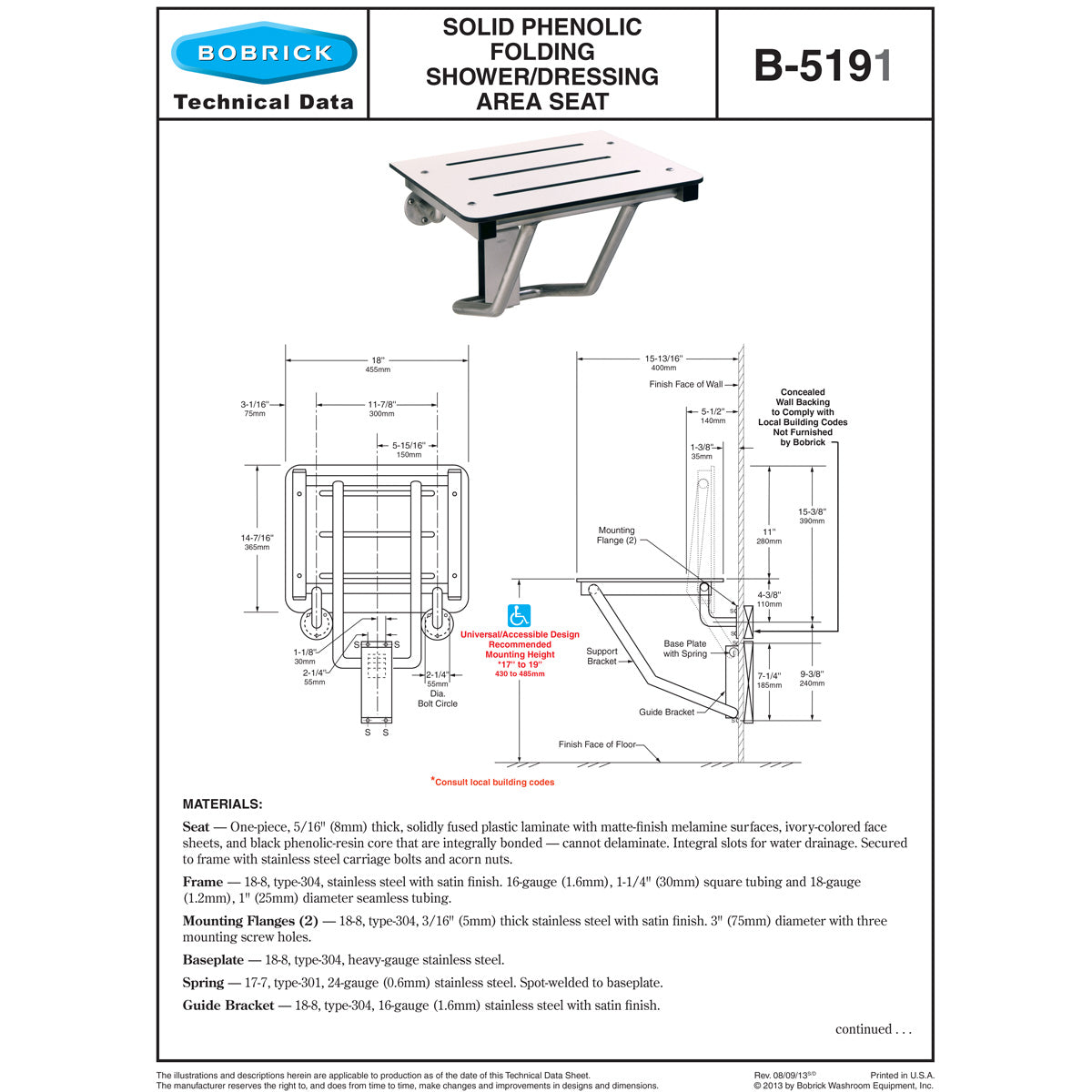

This shower seat features a compact design. The seat is made of durable, water - resistant, ivory - colored 5/16' (8mm) thick solid phenolic. The frame and mounting bracket are crafted from type 304 stainless steel and have a self - locking mechanism. When properly installed, it can support up to 500 lbs (227 kg). The seat is 18' (455mm) wide and projects 15 13/16' (400mm) from the wall. Safety is a top priority. Shower seats rely on the strength of the anchors and walls they're attached to. They must be firmly secured to handle the intended loads. Always consult and follow local building codes. If the seat isn't adequately secured to the wall, building owners or maintenance staff should take it out of service. To keep users safe, don't use the seat to support weights over 500 lbs (227 kg), as this could lead to seat malfunction and potential injury. The seat is a one - piece, 5/16' (8mm) thick solidly fused plastic laminate with matte - finish melamine surfaces, ivory - colored face sheets, and a black phenolic - resin core that won't delaminate. It has integral slots for water drainage and is secured to the frame with stainless steel carriage bolts and acorn nuts. The frame is 18 - 8, type - 304 stainless steel with a satin finish, made of 16 - gauge (1.6mm), 1 - 1/4' (30mm) square tubing and 18 - gauge (1.2mm), 1' (25mm) diameter seamless tubing. The mounting flanges, baseplate, spring, and guide bracket are also made of high - quality stainless steel. The shower seat can be folded up against the wall when not in use. The spring at the top of the baseplate locks the seat in an upright position until you pull the top of the seat away from the wall. The support system with a guide bracket allows for different mounting heights and makes floor cleaning easier. The non - porous solid phenolic seat has slots for water drainage, won't splinter, doesn't need oiling, and won't support bacteria growth. The slotless round - head carriage bolts and acorn nuts add extra safety. When properly installed, it meets accessible design guidelines. For installation, secure the unit to the wall at the marked points. The mounting height must comply with local building codes. For stud walls, use concealed backing and the provided stainless steel sheet - metal screws. For prefabricated shower stalls, rely on the backing provided by the manufacturer and the supplied mounting screws. Bobrick offers a mounting kit; order 252 - 30 for additional kits. For masonry walls, use fiber plugs, expansion shields, toggle bolts, or expansion bolts. Mount the Safety Plate on the wall near the shower seat at a minimum height of 30' (760mm) to meet A.N.S.I. Standards.

Using this shower seat is easy. When you're not using it, you can fold it up against the wall. Just pull the top of the seat away from the wall to release the spring and unfold it for use. But there are some important things to keep in mind. First, make sure to install it according to the local building codes. The seat is only as strong as the anchors and the wall it's attached to, so it must be firmly secured. If you notice that the seat isn't well - attached to the wall, don't use it and have it fixed or removed. Also, never use the seat to support more than 500 lbs (227 kg) to avoid malfunction and potential injury. As for maintenance, the non - porous solid phenolic seat is great. It has slots that let water drain out, so you don't have to worry about water pooling. It won't splinter or need oiling, and it won't support bacteria growth. Just give it a regular wipe - down to keep it clean. And remember to check the bolts and nuts from time to time to make sure they're tight. If you need to install a Safety Plate, mount it on the wall near the seat at least 30' (760mm) high to inform users about the weight restrictions.